Last Update: July 10, 2015

Conventional Oil - Traditional oil wells

Extracting "conventional oil" may be the simplest crude oil resource to tap, but that doesn't make for zero environmental impact.

Drilling sites have to be prepared with effects including ground clearing, grading, drilling, waste management, vehicular and pedestrian traffic, and construction and installation of facilities. There are access roads to build, pipelines to install, and other facilities like pumping stations. This converts what had been wilderness (perhaps) into industrialized land. For example, "ground clearing" around any of these facilities means removing all vegetation and animal life, and paving everything with gravel or even tarmac. [TribalEnergyInformationClearinghouse1] [EPA1]

The wilderness that's been converted into industrialized land no longer sustains the wildlife that had formerly lived on that land.

Active drilling operations are noisy, with sound levels as high as 115 dBA at the drilling site. Drilling occurs 24 hours a day for two months or more at a stretch.

Once the well is drilled, it will be pumping oil out of the ground for transportation elsewhere. There's plenty of opportunity for oil spills at the drilling site, or during transportation elsewhere.

On-site Air emissions at oil wells

When all goes right at the oil well, the majority of "emissions" are from on-site vehicles or generators. However, crude oil contains a lot of toxic contents, and some of it escapes at the well site. If nothing else humans are imperfect and make mistakes, which means the occasional oil spill. Some are small, some are huge, but each one releases toxicity into the environment. The range of air emissions includes volatile organic compound (VOCs), nitrogen oxides, sulfur dioxide, carbon monoxide, benzene, toluene, ethylbenzene, xylenes, polycyclic aromatic hydrocarbons (PAHs), hydrogen sulfide, particulates, ozone, and methane. [TribalEnergyInformationClearinghouse2]

Because underground high pressure usually dissolves natural gas into crude oil, that natural gas is released from the crude oil once it reaches the lower pressure we have at the surface. Natural gas is primarily methane, making it a more potent greenhouse gas than carbon dioxide. Often the natural gas simply vents into the atmosphere. Sometimes it is captured and sent by the well operator to the market. Other times it is flared (burned) at the site, converting it into carbon dioxide.

Produced Water at conventional oil wells

Produced Water often comes out of wells, when it co-exists in the geological formation being drilled. [COGA] This water is often laden with many chemicals, some toxic, and can be radioactive with "normally occurring radioactive materials" (NORM). The produced water has to be disposed of somewhere, often that's by pumping it underground somewhere. Some are looking into cleaning up produced water and putting it to use elsewhere, because not all produced water is "contaminated". [GreelyTribune] The trucks carrying produced water to disposal sites sometimes crash, leaking the water and its unknown chemical contamination, and in any case tear up the roads. [TexasObserver] They're even thinking of spraying produced water on gravel roads to reduce dust. [ColoradoEnergyOffice]

As an oil field ages the rate of produced water increases. [ProducedWaterSociety] Produced water at offshore rigs might just be dumped into the ocean, or else reinjected underground at the site. [OffshoreEnvironment1] and [OffshoreEnvironment2] [BureauOceanEnergyManagement]

We have a lot more to say on produced water below when we discuss fracking. But first we have to talk about oil spills.

Oil spills & accidents

Humans are fallible, and the machines we make breaks or otherwise we cause accidental unwanted results. In some cases that results in spilling highly toxic chemicals like crude oil into the environment. Every industry has its record of accidents, spillage of toxic stuff, or even deaths of workers or innocent bystanders.

Oil spills can occur in any phase of the oil lifecycle. An oil drilling rig may break or even explode as happened in the Deepwater Horizon disaster, or a pipeline may break, or an oil train can derail, a refinery can explode, a gasoline tanker truck can crash, a gasoline station can have leaky storage tanks, etc. The common result is that the oil, instead of making its way to an end customer, instead is released directly into the environment.

How different is a crude oil spill from any other day? In its normal application, crude oil is not directly spilled into the environment, but is transported to refineries, made into oil products, etc. But those refined crude oil products do make their way into the environment every day. Every ounce of crude oil is turned into one sort of product or another (gasoline, etc). Every day those products are used, releasing every ounce of crude oil chemical content into the environment. Does that mean every day all day long we effectively have a planet-wide oil spill?

The difference between an oil spill and any normal day is that spilled crude oil or oil products concentrate the entire toxic load in one place. The normal use of crude oil products spreads the toxic load release out over a wide area, and some the toxic constituents are removed during the refining process.

At the same time what happens to all the toxic chemicals we mentioned earlier? We'll go over this question further down when discussing the CONSUMPTION phase.

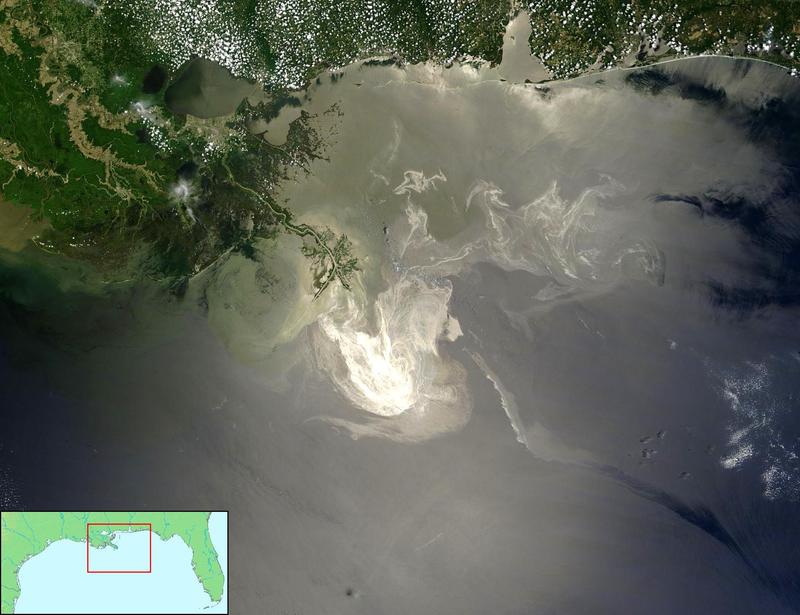

Deepwater Horizon - May 24, 2010

In April 2010, the Deepwater Horizon oil rig in the Gulf of Mexico blew up, tilted over, and partially sank. The wellhead was under 5,000 feet of water, drilling to a depth of 18,360 feet (5,600 m), making it extraordarily difficult to cap the well. The result was over 4.9 million barrels of crude oil spilled into an area we collectively depend on for our seafood supply. It damaged wetlands along the Louisana coast, with oil being found as far away as the Florida Panhandle. Sealife in the area have been poisoned and are dying at much higher than the usual rate. [Wikipedia1] In an attempt to stop or mitigate the crude oil spill, BP sprayed Corexit and other oil dispersants. This product (COREXIT) has carcinogenic, hazardous toxins and endocrine-disrupting chemicals. [Wikipedia2] Yes, carcinogenic hazardous toxic chemicals being poured into the ocean to negate the negative effect of carcinogenic hazardous toxic crude oil being released into the ocean?

Because conventional oil resources are harder to come by - the easy oil fields have all been tapped - the oil companies are having to go further and further afield. Deepwater oil drilling, like the Deepwater Horizon, is one effect, and another is the attempts to launch oil drilling activities in the arctic. There are whole oil fields in the arctic waiting to be tapped, and thanks to global warming causing the ice cap to shrink it's now becoming possible to do so.

As horrible as that event was, it's by far not the only oil spill. Instead, we routinely have oil spills of all kinds from all kinds of oil industry infrastructure. [Wikipedia3] [USNEWS] [TelegraphLondon] [UNEP] [NIHCrudeOilHealth]

Mitigating crude oil spills with Dispersants

One of the go-to-techniques for mitigating an oil spill are dispersants, like Corexit. Dispersants are chemical compounds that break down crude oil into smaller particles, allowing the oil to mix more freely with water. The hope is that less crude oil makes it to shore, limiting the impact on shorelines, and limiting the impact on surface marine life. The problem is that the widely used dispersants make the situation far more toxic than it already was, and by mixing the oil into the water it becomes more bio-available to marine life, and has been found to sink to the ocean floor. (see Crude Oil Dispersants – The main tool to mitigate crude oil spill disasters for more information)

Heavy Oil Extraction

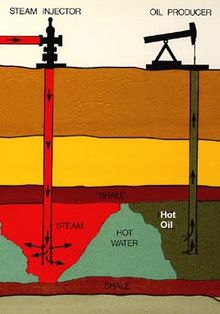

This is crude oil that's thicker, or more viscous, than "regular" (light) crude oil. That it's thicker it doesn't easily flow out of a well, requiring more work to extract. Typically, this means pumping steam underground to melt the viscous stuff. This costs lots of water and energy to convert that water to steam. [Wikipedia4] [Elk Hills Petroleum]

The resource use, water and the energy to make steam, is an environmental impact. According to the Wikipedia, this means "the extraction and refining of heavy oils and oil sands generates as much as three times the total CO2 emissions compared to conventional oil".

Heavy oil also has more sulfur, nickel, and vanadium content, which must be removed during the refining process.

At many of the tar sands oil resources discussed below, the steam injection technique is also used for the same purpose.

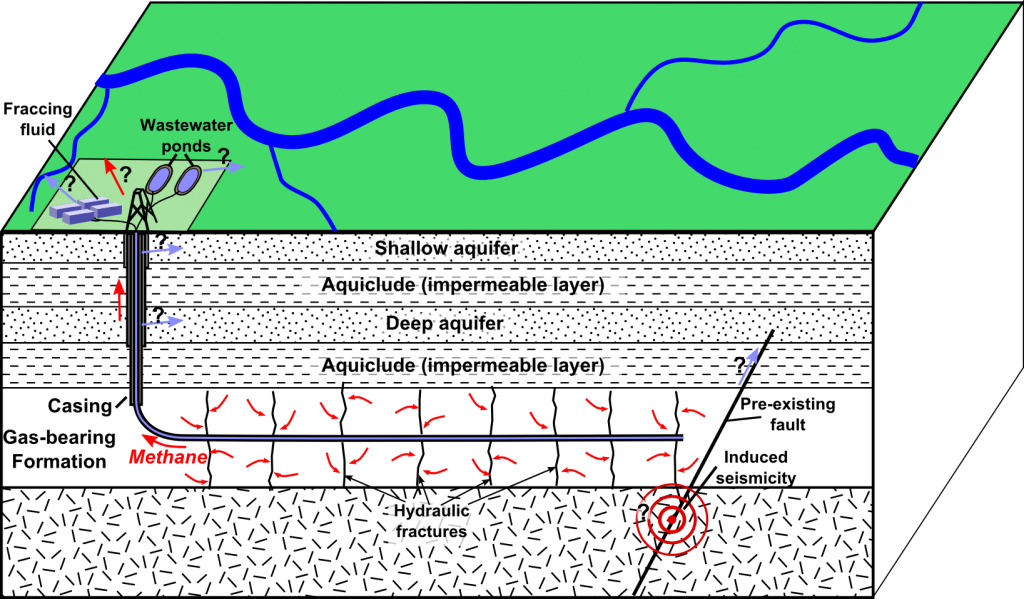

Unconventional Oil - Fracking & oil

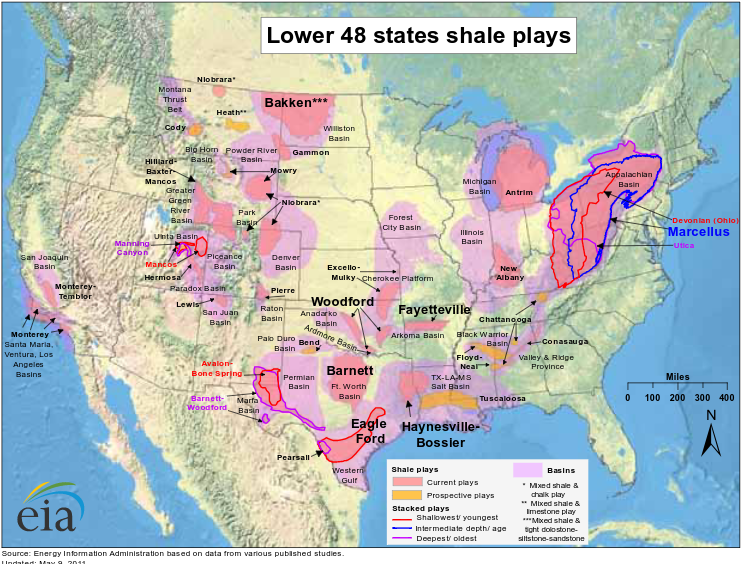

Hydraulic Fracturing, a.k.a. fracking, is a process where first a hole is drilled underground and lined with cement. The hole is drilled into a shale formation from which oil companies hope to extract either crude oil or gas, with horizontal drilling fanning out into the shale formation. The hydrocarbons in shale formations are tightly bound with rocks (shale), making it impossible to extract through normal means. A mixture of water, sand and "chemicals" (known to be highly toxic) are pumped underground at high pressure with the intent of fracturing (breaking) the underground rock formations. The sand is meant to prop open the cracks. After cracking the underground rock formations, oil or gas will become available to extract. [FracFocus] [EPA2] [EarthworksAction] [Wikipedia5] [DangersOfFracking] [AmericanPetroleumInstitute] [USGS1]

Fracking's effects on the water system

TODO FIX URL

Fracking can generate lots of produced water.

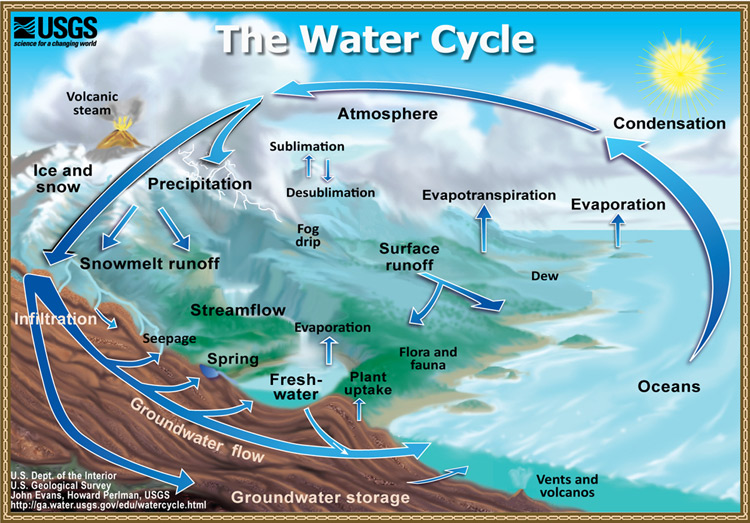

Hydraulic Fracturing, a.k.a. Fracking, consumes huge amounts of water, 3-5 million gallons per well. All of which is trucked to the site, mixed with sand and fracking chemicals, then pumped underground. Some of the water comes back to the surface -- about 10% -- the rest is "lost" underground, having been removed from the regular hydrological cycle. Special precautions must be undertaken to avoid taking too much water out of streams so that others can use that water. [USGS2] [PITT.EDU] [DailyKos] [USBR] [LATIMES1] [NRDC]

It's estimated that in the U.S. over 250 billion gallons of water have been used in fracking operations since 2005. [OilPrice.com] [ViceMotherboard] It's worth reiterating that the vast majority of water used in fracking operations is removed from the hydrological cycle. That's fresh water that's no longer drink available for use by us or the plants and animals surrounding us. The number, 250 billion gallons, is way too large for us to conceptualize, but

a helpful USGS website helps us conceptualize a million gallons of water. A million gallons is a cube of water measuring 51 feet on each side, or a pool measuring 267 feet by 50 feet by 10 feet deep which is almost the size of a football field. The 250 billion gallons used in fracking is 250,000 of those cubes of water.

The hydrologic cycle, pictured above, is the cycle of water between land, ocean, atmosphere, plants, and animals, that keeps the flow of life circulating. We already have a world-wide water crisis thanks to increasing population and increasingly arid conditions in many places. It's not helped by a wholesale removal of water from the hydrological cycle.

In areas where it's dry, like the Western US, that amount of water is the difference between life and death. It also makes the produced water coming from these operations of interest, if it can be cleaned up to the point of being of beneficial use.

Fracking uses a wide range of toxic chemicals to induce fractures in underground shale & rock formations. It's known that many of the chemicals are highly toxic, but the companies are refusing to divulge the chemical make-up citing trade secret protections. In some cases the chemicals get into drinking water supplies, from leaking wells, well blowouts, and spills. [EnvironmentAmerica]

People living close to fracking sites are exposed to air pollutants including volatile organic compounds (VOCs) such as benzene, xylene and toluene which are known to cause a wide range of health problems -- from eye irritation and headaches to asthma and cancer. The Texas Department of Environmental Quality has detected benzene levels so high as to be an immediate human health risk, at two sites in the Barnett Shale region. At 19 other sites the benzene concentration was a little lower, posing a health risk for long term exposure. Benzene is a known carcinogen.

It's known that lots of natural gas (a.k.a. methane) leaks out of fracked wells, worsening the greenhouse gas, climate change and environmental impact of such wells. In 2012 the EPA instituted rules capping emissions at fracked wells. [NYTimes] [EPA3] To do so they'll be required to capture the natural gas, which they can sell into the market.

Methane leaks from fracking operations at several stages, either intentionally or accidentally. Natural gas seepage from broken well casings have been shown to contaminate ground water. Methane has over 25 times the heat-trapping ability of carbon-dioxide.

The companies involved don't always follow the law when setting up a drilling site, or disposing of the produced water. They've been observed spraying contaminated produced water on peoples fields, without permission, poisoning those fields. They've used old gas leases signed by previous land owners as justification to destroy peoples land in order to set up a drilling site. [WeAreCovePoint] In Kern County, CA, it's been discovered that oil producers illicitly set up hundreds of produced water disposal ponds in land next to agricultural land. None of the pits had linings to prevent seepage into the ground, nor nets to prevent birds from landing in the water. [LATimes2]

Oklahoma and southern Kansas, an area that's otherwise geologically quiet, have been subjected to routine earthquakes over the last several years. The same is happening in Ohio. In Oklahoma, the earthquakes began in 2009 and have been steadily increasing since. [USGS3] It's been discovered that Oklahoma had "hidden faults beneath the surface ready to pop". Fracking operations, and the disposal of produced water by underground injection, have lubricated those faults into activity. Another series of earthquakes in north Texas is causing the USGS to consider upgrading the earthquake risk in that area. [DallasNews] [NationalGeographic], [NatGeographic] [USGS4], [USGS5] [Cleantechnica] [TheVerge] [Time] [ScienceDaily] [CAFrackFacts] [TheTyee] [CRS] [CNBC] [FuelFix] [ThinkProgress]

USGS scientists have determined that large areas in the U.S. which formerly had few, or no, earthquakes are now seeing a "remarkable increase in earthquake activity". This is not the result of natural processes, says the USGS. [USGS6]

Instead, the increased seismicity is due to fluid injection associated with new technologies that enable the extraction of oil and gas from previously unproductive reservoirs. These modern extraction techniques result in large quantities of wastewater produced along with the oil and gas. The disposal of this wastewater by deep injection occasionally results in earthquakes that are large enough to be felt, and sometimes damaging. Deep injection of wastewater is the primary cause of the dramatic rise in detected earthquakes and the corresponding increase in seismic hazard in the central U.S.

Not all areas with fracking operations have earthquake activity. For example, North Dakota has lots and lots and lots of fracking operations but very few earthquakes. It's thought that for fracking to induce earthquakes, the injected water must find its way to a fault. Hence, if there's no geologic fault the fracking operations won't induce earthquakes.

Unconventional Oil - Tar sands oil

Oil sands (tar sands) generally are an extra-heavy crude oil or crude bitumen trapped in unconsolidated sandstone. These hydrocarbons are extremely dense and viscous, with a consistency similar to molasses in some cases, to as solid as peanut butter in other cases. This makes extraction extremely difficult, and huge amounts of water is required to separate the oil from the sand. Because they're so thick, such deposits cannot be transported to refineries without either heating (to melt the bitumen) or diluting it with lighter oils. These deposits often also contain sulfur and heavy metals such as vanadium, nickel, lead, cobalt, mercury, chromium, cadmium, arsenic, selenium, copper, manganese, iron and zinc. In many cases it's difficult to refine these oils at refineries, without making major modifications. [Wikipedia6], [Wikipedia7] [CRS]

Tar sands deposits exist in several places, with those in Alberta being the most contentious. The massive formation there is the size of Florida, and is covered by Boreal forest. Because extracting tar sands oil starts with what's essentially strip mining, vast areas of forest land are being destroyed. [NRDC]

Tar Sands Oil Extraction Methods

Extraction methods for tar sands are:-

Surface Mining (a.k.a. strip mining) The Athabasca tar sands in Alberta Canada are the only such formation that's shallow enough to strip off the surface. The "overburden" is water-laden muskeg (peat bog) over top of clay and barren sand, or the Boreal forest mentioned earlier. The oil companies strip that away, then start scooping up the bitumen and trucking it to a processing plant. The tailings ponds, which collectively cover an area of over 77 square kilometers, contain suspended solids and other dissolvable chemical compounds such as acids, benzene, hydrocarbons residual bitumen, fine silts (mature fine tails MFT), and waste.

Cold Heavy Oil Production with Sand (CHOPS) For Heavy Oil operations, they've found that removing the sand filters allowing sand to be produced along with the oil, that production rates improved significantly. This opened up caverns underground that then allowed more oil to reach the wellbore.

Cyclic Steam Stimulation (CSS) Some tar sands fields operate like heavy oil fields, and the oil companies use steam injection to recover oil.

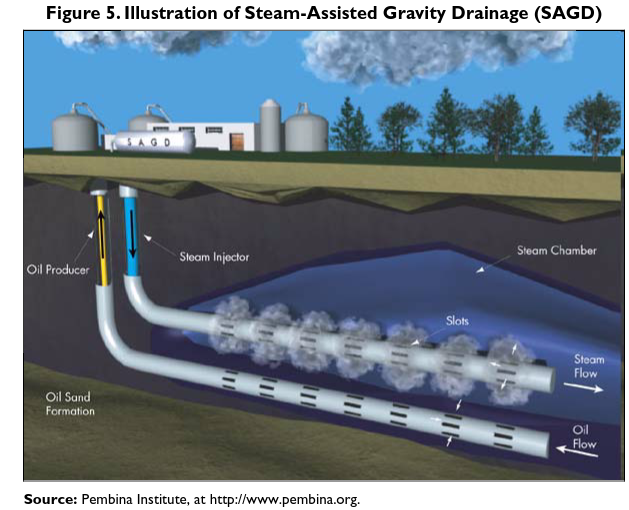

Steam Assisted Gravity Drainage (SAGD) This involves drilling a pair of wells, one directly above the other. The upper well is used to inject steam, while the lower well collects the oil which melts. Also used are horizontal drilling techniques so the wells can continue outward for miles.

Vapor Extraction (VAPEX) Instead of injecting steam into a well, they'll inject solvents designed to separate the bitumen from the sand.

Toe to Heel Air Injection (THAI) Instead of injecting steam to melt the bitumen, they'll set fire to the underground bitumen. It's tricky to accomplish this without blowing things to smithereens. The advantage is that the oil company doesn't have to expend energy to create steam, if they can control the process well enough.

Combustion Overhead Gravity Drainage (COGD) This is like mixing SAGD with THAI, setting fire to the bitumen, above an area where one or more horizontal wells have been drilled to collect melted bitumen.

Other than the strip mining approach, these approaches all involve heating the bitumen in-place underground, making it easier to extract through a well. Every one of these approaches involve extra amounts of machinery, technology development, energy and resource inputs, etc.

In the Alberta Tar Sands region, 715 square kilometers (276 sq mi) of land has been stripped bare to expose the tar sands underneath. Canada's government claims to mandate that the oil companies will restore the land after they're done destroying it. 72 km2 (28 sq mi) of that land is under reclamation. [AlbertaGovernmentOilSands]

Energy to Heat/Melt Tar Sands Oil

The energy required to create the steam used to melt these viscuous bitumens decreases the return on investment (EROI), or the energy gain derived from producing this oil. For example it's thought the energy required is 1.0-1.25 gigajoules (280-350 kWh) of energy to extract a barrel of oil from bitumen. That barrel contains about 6.117 gigajoules (1,699 kWh) meaning an energy gain of only 5-6x. [LifeCycleAssociates] [AlbertaEnergy]

As we asked elsewhere, is this the best use of those resources? The 1.0-1.25 gigajoules figure here is one estimate, which may not be accurate, however it is accurate to say that these processes require energy and other resources that in theory could be put to other uses.

Toxic Air Emissions at Tar Sands sites

Air quality in that area is degraded, with toxic pollutants some of which are carcinogens, including benzene and styrine. Snow and water samples taken from the area show high concentrations of pollutants associated with fossil fuels, known as polycyclic aromatic hydrocarbons (PAHs), chemicals that are known to damage DNA, and are carcinogenic.

It shouldn't be a surprise to learn the Alberta Tar Sands area has an elevated rate of leukemia and other cancers. There have been years of reports by residents of odors that make them sick, including nausea, headaches, skin rashes, memory loss, joint pain, exhaustion, and respiratory problems.

Toxic Waterway Emissions at Tar Sands sites

Polycyclic aromatic hydrocarbons (PAHs) in the Athabasca river and many lakes in the region are above allowable levels. It includes benzo(a)pyrene, a chemical that has been linked to cancer, genetic damage, reproductive impacts including birth defects, and organ damage. Another chemical, Methylmercury, found in water samples is a potent neurotoxin that causes developmental and behavioral problems, including lower IQ in children, as well as cardiovascular effects in adults. It bioaccumulates in the foodchain, giving unhealthy levels of exposures to peoples who consume a lot of locally caught fish, like the First Nations people of that area.

The tailings ponds include multiple toxic chemicals including arsenic, benzene, lead, mercury, naphthenic acid, and ammonia. As much as 2.9 million gallons of water leaks from tar sands tailings ponds into the environment every day. The PAH's may also be evaporating into the atmosphere.

Diluting Agents required to Transport Tar Sands Oil

Diluting agents used to allow the bitumen to be moved into and out of railcars or pipelines have proprietary formulations. While the specific makeup is a secret, it's known that natural gas liquid condensate containing volatile hydrocarbons such as benzene, toluene, ethyl benzene and xylene are used. During transfers between transportation vessels, some of those chemicals are known to evaporate into the atmosphere. These chemicals are highly toxic.

When the resulting synthetic crude oil makes its way to a refinery, it is far more toxic than regular crude oil. In addition to the diluting agents, it also contains 102 times more copper, 11 times more nickel, and 5 times more lead than conventional crude oils, with various constituents being released into the atmosphere.